Going GREEN With LEAN

Zachary Metzger, Savannah Richardson, Marta Söderlund, and Erika Vaudrin

BSU Environmental Studies Program, Idaho Department of Environmental Quality

Project Goal

Use principles of Six Sigma LEAN and QiMacros Software to reduce waste and implement sustainable solutions in workplaces throughout the treasure valley.

Six Sigma LEAN Class (TechHelp)

- 32 hours classroom instruction

- Experience working with QiMacros Statistical Software

LEAN Principles

- LEAN: Focuses on waste reduction by streamlining a process

- Six Sigma: Focuses on preventing defects through problem solving

- Together, LEAN and Six Sigma provide a comprehensive tool set that can be used to increase the speed and effectiveness of any process

- Qi Macros Software used as a tool to accelerate LEAN

Treasure Valley Businesses

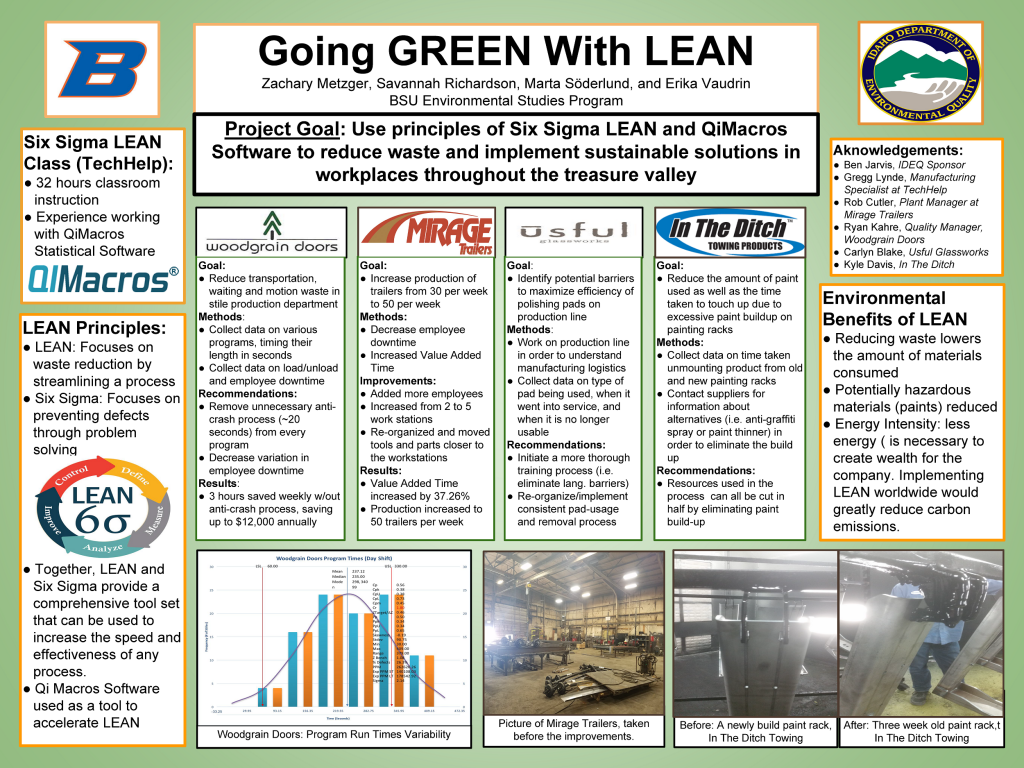

Woodgrain Doors

- Goal: Reduce transportation, waiting and motion waste in stile production department

- Methods: Collect data on various programs, timing their length in seconds; Collect data on load/unload and employee downtime

- Recommendations: Remove unnecessary anticrash process (~20 seconds) from every program; Decrease variation in employee downtime

- Results: 3 hours saved weekly w/out anti-crash process, saving up to $12,000 annually

Mirage Trailers

- Goal: Increase production of trailers from 30 per week to 50 per week

- Methods: Decrease employee downtime; Increased Value Added Time

- Improvements: Added more employees; Increased from 2 to 5 work stations; Re-organized and moved tools and parts closer to the workstations

- Results: Value Added Time increased by 37.26%; Production increased to 50 trailers per week

USFUL Glassworks

- Goal: Identify potential barriers to maximize efficiency of polishing pads on production line

- Methods: Work on production line in order to understand manufacturing logistics; Collect data on type of pad being used, when it went into service, and when it is no longer usable

- Recommendations: Initiate a more thorough training process (i.e. eliminate lang. barriers); Re-organize/implement consistent pad-usage

and removal process

In the Ditch Towing Products

- Goal: Reduce the amount of paint used as well as the time taken to touch up due to excessive paint buildup on painting racks

- Methods: Collect data on time taken unmounting product from old and new painting racks; Contact suppliers for information about alternatives (i.e. anti-graffiti spray or paint thinner) in order to eliminate the build up

- Recommendations: Resources used in the process can all be cut in half by eliminating paint build-up

Environmental Benefits of LEAN

- Reducing waste lowers the amount of materials consumed

- Potentially hazardous materials (paints) reduced

- Energy Intensity: less energy ( is necessary to create wealth for the company. Implementing LEAN worldwide would greatly reduce carbon

emissions

Acknowledgements

- Ben Jarvis, IDEQ Sponsor

- Gregg Lynde, Manufacturing Specialist at TechHelp

- Rob Cutler, Plant Manager at Mirage Trailers

- Ryan Kahre, Quality Manager, Woodgrain Doors

- Carlyn Blake, Usful Glassworks

- Kyle Davis, In The Ditch