Brielle Ibe, Hunter Good, Dr. Jake Benzing, Dr. Michael Hurley

Abstract

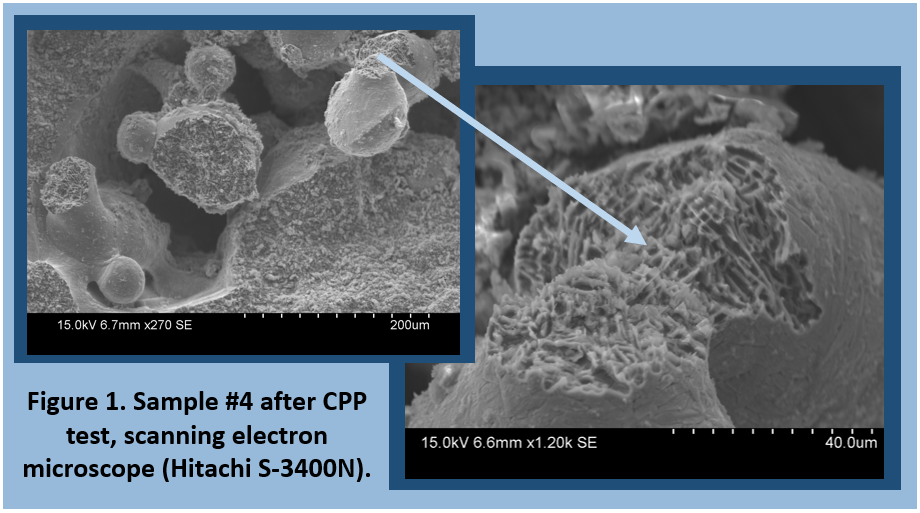

The versatility and affordability of additive manufacturing (AM) techniques has revolutionized metal manufacturing, processing, and prototyping. As additive manufacturing increasingly replaces other methods of titanium production, it is important to research the correlation between the corrosion behavior of AM Ti-6Al-4V parts and AM build parameters. Five electron beam melted (EBM) AM Ti-6Al-4V rectangular rod samples were built with varying scanning lengths. These scanning lengths dictated the proportions of different prior-beta grain crystallographic orientations and the presence (or absence) of “lack-of-fusion porosity” defects. Each sample was cut, mounted in epoxy, and tested with cyclic potentiodynamic polarization (CPP) scans in 3.5 wt% NaCl electrolyte to differentiate corrosion behavior. Pitting potential, primary open circuit potential at the beginning of a scan, secondary open circuit potential at the end of a scan, passive current density, and return beak potential values were extracted from CPP scans to compare each sample’s corrosion resistance. The purpose of this research is to determine how AM build parameters influence corrosion behavior and performance in AM Ti-6Al-4V alloy. [1-4]

References

[1] Benzing, Jake. “Benzing_TMS slides for Boise State poster at NACE.pptx,” Unpublished PowerPoint slides (2020). National Institute of Standards and Technology.

[2] Email and video conference communication with Dr. Jake Benzing and his team at NIST. National Institute of Standards and Technology.

[3] Abdeen, Dana H., and Bruce R. Palmer. “Corrosion evaluation of Ti-6Al-4V parts produced with electron beam melting machine.” Rapid Prototyping Journal (2016).

[4] Yang, Jingjing, et al. “Corrosion behavior of additive manufactured Ti-6Al-4V alloy in NaCl solution.” Metallurgical and Materials Transactions A 48.7 (2017): 3583-3593.

Authors and Contributors

- Hunter Good, Boise State University Micron School of Materials Science and Engineering, huntergood@u.boisestate.edu

- Brielle Ibe, Boise State University Micron School of Materials Science and Engineering, brielleibe@u.boisestate.edu

- Dr. Jake Benzing, National Institute of Standards and Technology (NIST).

- Dr. Nikolas Hrabe, National Institute of Standards and Technology (NIST).

- Dr. Mike Hurley, Boise State University Micron School of Materials Science and Engineering.

Acknowledgements

- National Institute of Standards and Technology (NIST).

- Boise State University Applied Electrochemistry and Corrosion Research Laboratory.

- Boise State Center for Materials Characterization (BSCMC).

- Boise State University Micron School of Materials Science and Engineering (BSU MSMSE).

Additional Information

For questions or comments about this research, contact Brielle Ube at