By Lilly Crolius

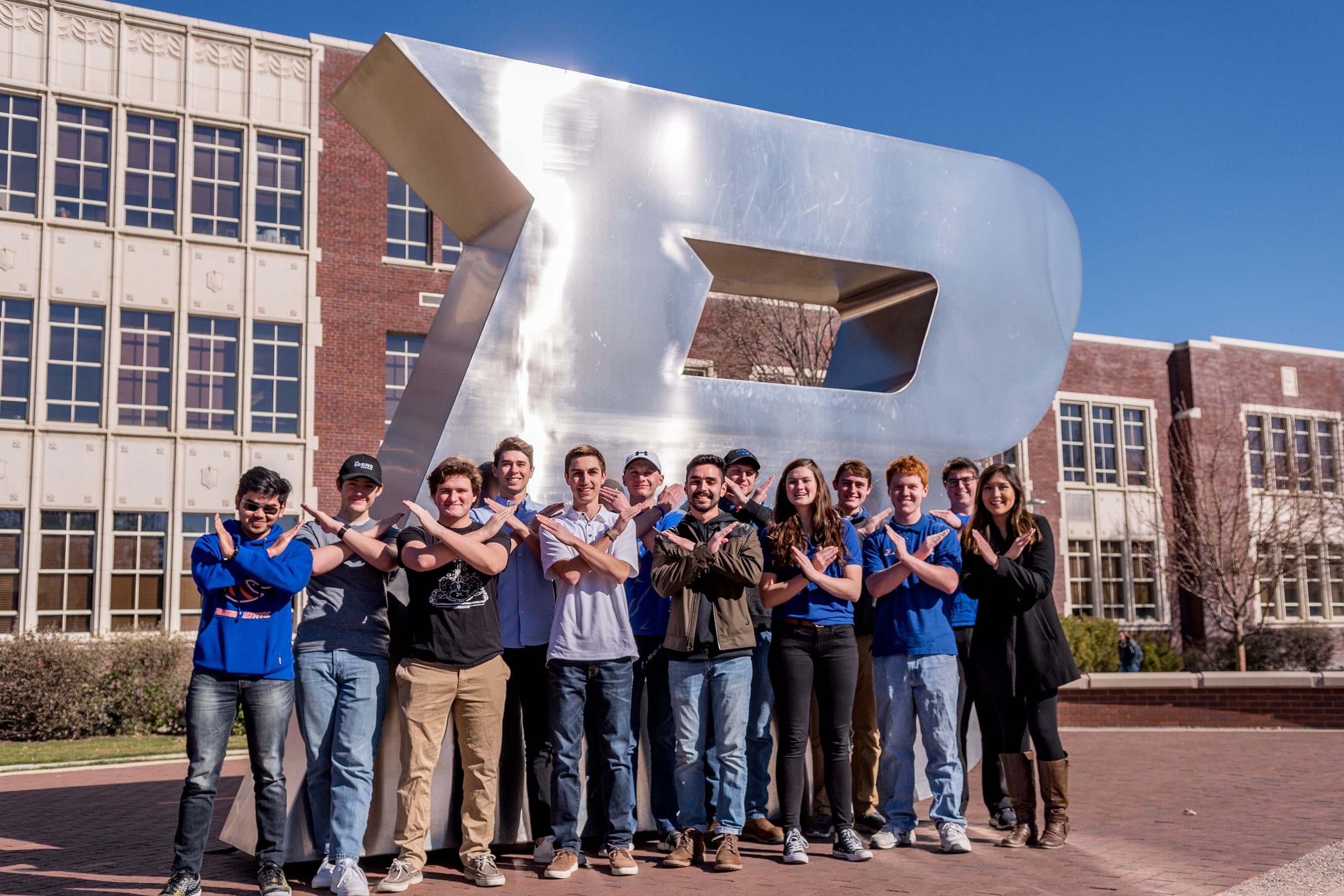

Boise State University is no stranger to students taking the lead on scientific discovery and research, and for the past four years Boise State’s Microgravity Undergraduate Research Team has been at the forefront of this student engagement.

This year, on May 21-24, a group of 15 undergraduate students once again will compete in NASA’s MicroG-NExT program against 21 other universities from across the nation. This competition is hosted by NASA each year not only to find solutions to some real-life obstacles the organization has encountered, but also to provide a way for students to gain hands-on industry experience.

For months, Boise State’s team has been hard at work designing a tool to seal holes in the International Space Station.

“NASA gives teams four challenges to choose from. This year we chose the module leak repair system. If there’s a hole in the international space station, we have to repair it – in zero gravity. Holes can be as small as one-fourth to one inch, and come in different angles and different types. We have to be able to repair all of them,” explained Olivia Maryon, a sophomore who is majoring in materials science and engineering, with a minor in computer science. Maryon is one of two team leads this year.

Amidst a recent international push for technological innovation, it’s no surprise that the majority of the students come from STEM fields.

“Most team members on the team this year are mechanical engineering majors with one materials science and engineering major,” said the other Microgravity team lead, Marcus Marosvari, a junior majoring in mechanical engineering, with a minor in computer science.

However, former astronaut and Boise State distinguished educator Steve Swanson feels that the biggest advantage the Microgravity team gains through the nearly year-long exercise is a greater diversity of thought.

“The design and building the tool is mostly a mechanical engineering task, but I believe having a diverse team is always better. If the team is comprised of people with different backgrounds and knowledge, then the solution space is bigger and the possibility of getting a better solution is greater,” he said.

During their weekly meetings, the dedication and commitment each student put forth on the project was apparent. When a challenge arose, it seemed that the room’s energy flowed together to synthesize a solution. Students openly presented diagrams and ideas that they had created on their own time, and each one was met with constructive feedback.

“To me, that is one of best features of this program,” said Swanson. The team members get many opportunities to practice their communication skills, to learn how to listen to others and how to combine their ideas together to create a great solution. “I believe working on a real-world engineering problem will give these students the opportunity to learn what it is like to work on a project from initial design through testing, including writing a proposal and test plan. This program will also improve their team skills, including communication, team care and leadership. And these experiences and skills are greatly desired by many companies looking to hire new graduates,” he said.

The team’s cohesiveness is understandable; NASA’s national application process is long and fiercely competitive. It began in August 2017, when NASA first published its four design scenarios for the year.

“During the fall semester, the team brainstorms and comes up with a concept to propose to NASA,” Marosvari explained. “The team has to write a technical report detailing the concept, including design components, fabrication plans, and safety considerations. Our team is also extensively involved in STEM outreach in the Boise area, which is highly valued in the proposal process.”

The Boise State microgravity team submitted a 25-page proposal on how they would address the scenario of their choice in early November. Since being chosen to fabricate their design, the team has met on a weekly basis to ensure their tool is successfully executed.

“I think starting to actually build the tool is the hardest part,” Maryon said. “It’s not that we don’t know where to start, it’s like which piece do we even start with? The hardest part? The easiest part? What materials should we even build with? Also, all the testing will be done in zero gravity. We don’t have any way to test that here and no one has experience in zero gravity.”

While roughly 30 students have worked on the tool for months, only six will travel to Houston to test their design in May.

“They’re called the Flight Team. The rest of the team is the Ground Team,” Maryon said, while adding that every member is equally important.

Even though the Microgravity team has received significant national recognition over the course of the past few years, its leadership makes a point to keep in mind the roots that helped sprout the success of the program. The Idaho Space Grant Consortium and Boise State University were both instrumental in providing support for the team.