One of the most inspirational aspects of the engineering field is the ability to see a problem and follow the impetus to create a solution. This often means designing something that has never been designed before, relying solely upon creativity, knowledge, curiosity and grit.

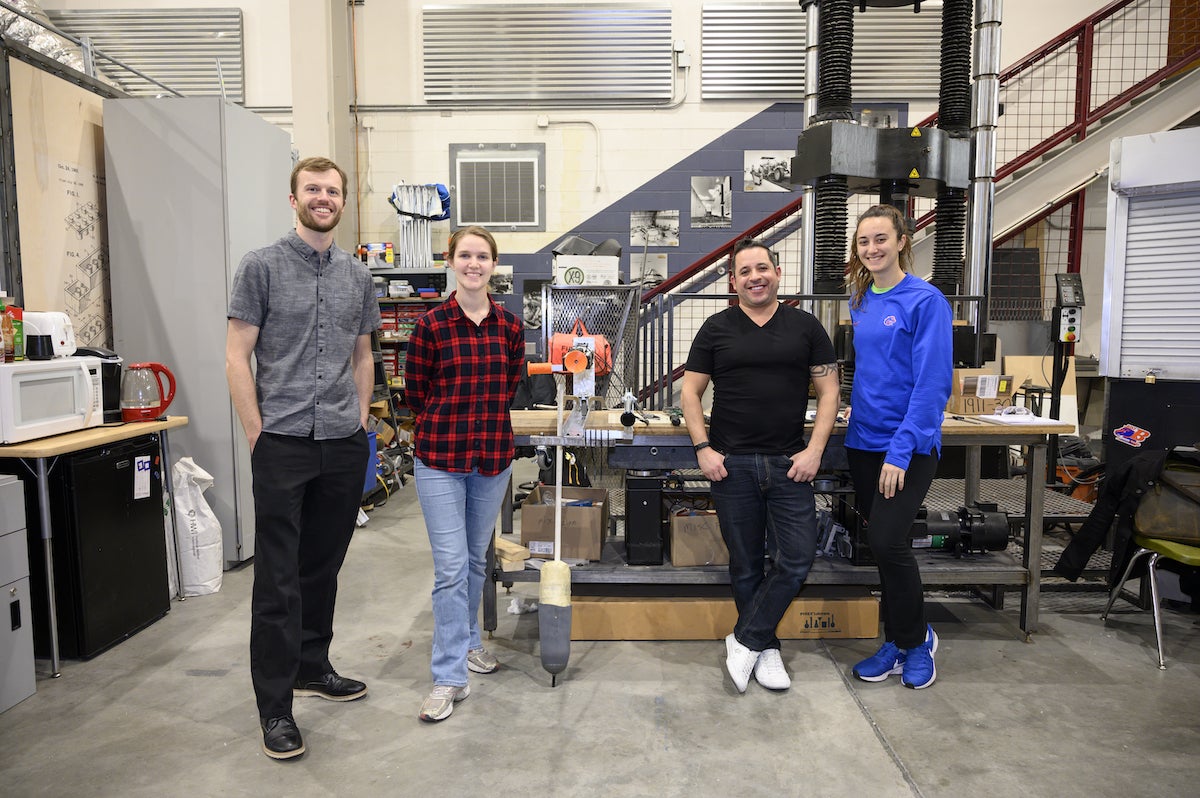

Take Boise State’s LYNR project for example. Four mechanical engineering seniors came together to design a machine that would assist below-the-knee amputees with putting on a necessary silicon gel liner that acts as a buffer between the body and the prosthetic limb. Working with local business Brownfield’s Prosthetics and Orthotics, and guided by capstone design manager Gus Engstrom, the team met with local amputees and identified this specific need that they could address with their skills as engineers.

“We presented our early concept and asked for their input and any other challenges that they have. They had all kinds of ideas and it was really helpful for us,” said team member Ryan Evans, who is pursuing his second bachelor’s in engineering, following a degree in biology.

According to the Amputee Coalition, there are nearly two millions people in the U.S. who live with limb loss.

“There are many amputees who struggle to put their prosthetic liner on by themselves due to issues with hand dexterity, strength, flexibility or even upper limb amputations,” said Amy Stone, a certified prosthetist/orthotist (CPO) at Brownfield’s. “A device that could ease this process would improve independence for this group of people.”

For Allyn Martinez, a veteran of the U.S. Marine Corps, the project was appealing because it offered the team a chance to design something completely novel. It also offered him the opportunity to serve the community of military men and women who suffered loss of limb in service.

“All of us like the humanity aspect of helping people and as a veteran, I know lots of amputees. So, we want to help that community,” said Martinez.

While all of the students are mechanical engineering majors, each brought a unique view from past experience or present passions to the project. Team member Alexandra Hoene found that her affinity for art gave her a valuable ability to see and communicate problems and solutions.

“Engineering is all about being able to picture your idea and explain it. And art gives you that opportunity to be able to look at your design, explain it and critique it, and hopefully make sure everyone knows it as well,” said Hoene.

Teammate Marta Hermida Herraez, who was recruited from Madrid, Spain, to play basketball at Boise State, says that this project is an opportunity for her to prepare for a career in biomedical engineering.

“If I can use my knowledge to help other people that will be my future goal. I think this [project] is probably the first step to be more and more into the biomedical field and the prosthesis,” Hermida Harraez said.

Brownfield’s CPO Eric Hinderager said working with the students was “nothing but positive.” He also noted the team’s high level of professionalism as well as Engstrom’s passion as an instructor.

“The students have been great, and it has been very interesting to hear their fresh ideas for a common problem,” Stone said.

LYNR has been working on their project in the recently expanded Engineering Innovation Studio, and Hoene says the space has made an enormous difference on their ability to create and learn.

“It’s awesome that we’re given the opportunity to learn how to use all the machines. We’ve been told that one of the difficult parts about being an engineer is you’ll design something and you’ll take it to the machinists and machinists will say, ‘Well, we can’t make it. It’s physically impossible to make that on a machine.’ So being able to come in here and make it ourselves, it’s a really important skill to learn and it’s fun getting your hands dirty,” said Hoene.

There are multiple opportunities on Dec. 11 to see how the College of Engineering is preparing its students to be the engineers of the future.

- See LYNR’s machine first hand 4-7 p.m. at the Senior Design Showcase at the Alumni and Friends Center Ballroom (1173 W. University Dr.)

- Tour the Engineering Innovation Studio from 4:45-6 p.m. at the Harry Morrison Civil Engineering Building (1019 S. Euclid Ave.)

Are you interested to see how students could advance your next company project or big idea? Book a slot in the 2020 cohort by contacting Gus Engstrom at gusengstrom@boisestate.edu.

– By Brianne Phillips