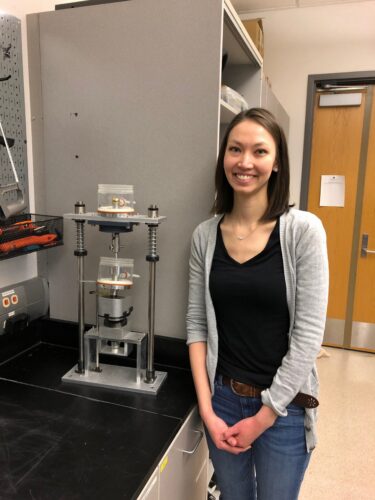

Katie Hollar examines a small, shell-like plastic through the lens of a camera. But this isn’t just an average piece of plastic nor is she using a standard camera. Hollar, a graduate student pursuing a master’s degree in mechanical engineering and a doctorate in material science and engineering at Boise State University, is viewing highly cross-linked polyethylene – a plastic liner commonly used in standard hip or joint replacement devices – through a structured light 3D optical scanner.

“Hip replacement devices last about 10-15 years, and young patients will outlive these replacements,” said Hollar. “Device longevity can be increased by either improving the materials or the device design, and we can use advances in imaging technology to assist this process.”

The medical industry is actively looking to better analyze and preserve the plastic liner inside hip and joint replacement devices. Over time, this plastic liner experiences a lot of wear as people walk or otherwise execute daily movements.

“For the scientists working to develop the next generation of implants, they need to understand the impact of their design decisions,” said Trevor Lujan, associate professor in mechanical and biomedical engineering at Boise State. “When you use new materials, when you redesign components, how does that affect wear? Being able to visualize wear is ultimately one of the most effective ways to evaluate device efficacy. Yet, almost no one is visualizing wear because there hasn’t been a fast and affordable technique.”

As an undergraduate student at Boise State, Hollar was inspired to look at durability and uneven wear in implants. She and her peers in mechanical engineering embarked on a process of producing and testing implants to come up with solutions.

The students partnered with WestVet, an emergency and veterinary hospital in Garden City, whose surgeons are interested in using thin liners made of highly cross-linked polyethylene in canine hip replacements. With the assistance of WestVet doctors, the group of student researchers created a machine that can simulate canine motion, giving them insight into the wear and tear of animal implants. The machine simulated canines trotting for one million “cycles,” which translates to approximately four months of activity. Using standard methods of weighing the plastic before and after testing, the researchers were able to measure the overall wear, but they couldn’t determine if specific locations had uneven or abnormal wear that would make it prone to cracking. They also learned that the only way to visualize wear was to use expensive equipment, such as coordinate measuring machines (CMMs) or laser scanners.

Through razor-sharp focus and rigorous research, Hollar discovered a groundbreaking solution: utilizing a 3D optical scanning technique that records millions of points on the liner surface in minutes rather than a standard CMM that goes point by point and therefore requires more time to execute.

“3D scanning is a very powerful and robust method,” Hollar explained. “Our method is so much faster than CMMs.”

“The resolution, quality and detail that Katie is able to get is better than what I’ve seen previously,” said Lujan. “Katie has shown an incredibly tenacity to use a new technology and create a new protocol that she proved could work.”

Hollar’s research – “Quantifying wear depth in hip prostheses using a 3D optical scanner” – was published in the research journal Wear, which then later caught the attention of a leading international source for engineering research news, Advances in Engineering, where it was featured.

“This was my first project that I saw all the way through from developing this methodology to publication,” said Hollar. “It’s rare to be able to see my work being published as an undergraduate.”

Her innovative process and technique also impressed the National Science Foundation, which awarded her with a graduate research fellowship that includes funding for three years of graduate education.

Under this current fellowship, Hollar is paving new ground for the future of joint health. Her focus has shifted from hips to knees, using 3D imaging to investigate the effect of wear on knee meniscus injuries that, as Lujan puts it, “are pervasive and have a very high societal cost.”

“I think that with how good imaging is becoming, it’s unavoidable that technology like optical scanners will play a bigger part in how we analyze the effectiveness of implants,” he stated. “We can use them in ways now that we couldn’t 10 years ago.”

Hollar hopes to continue making waves in the medical industry and beyond by developing innovative scanning and imaging techniques once she completes her doctoral program through Boise State, but her aspirations don’t stop there.

“After I’ve been in the biomedical industry and when I’m closer to retirement, I would like to return to academics to pass on knowledge to the future generation,” she said.