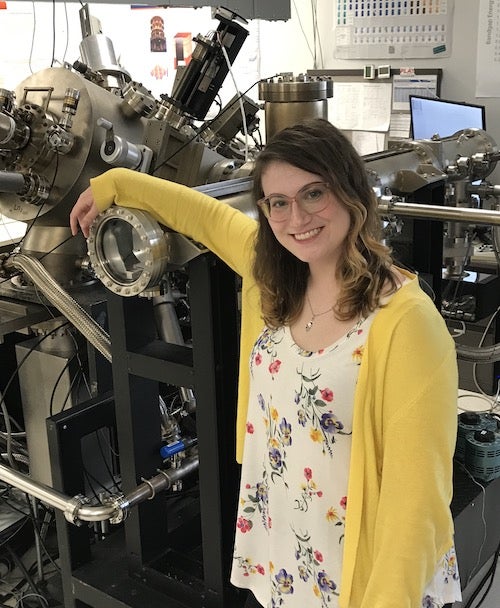

“My advisor, when I interviewed with him for the first time, described my project as magic, which I still find delightful and true. It is kind of like magic because we are actually changing the fundamental electronic structure of germanium to be useful for new applications,” said Katie Sautter, a third-year doctoral student in Boise State University’s materials science and engineering program.

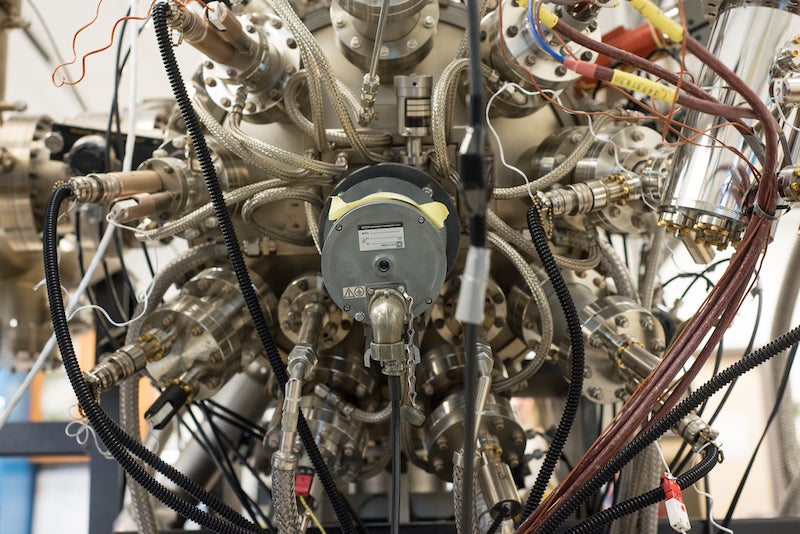

Under the mentorship of Paul Simmonds, an assistant professor in physics and materials science and engineering, Sautter and her colleagues recently published their findings about the epitaxy of the element germanium. Molecular beam epitaxy (or MBE) is a process by which beams of atoms or molecules of specific elements are injected into a vacuum chamber and then assemble themselves in a layer on a prepared surface.

These atoms are deposited layer by layer onto a surface, enabling scientists to grow nanocrystals, or quantum dots, with atomic precision. By changing the angle of surface on which dots grow, the researcher can even alter the element’s orientation and enable its bonds to stretch in new ways. Sautter and her team are working to use this technique to overcome some of germanium’s natural limitations.

Germanium is widely used in the electronics industry for making transistors and other components. However, unlike other semiconductors, germanium cannot emit light efficiently. That is why it can’t be used to make LEDs, for example.

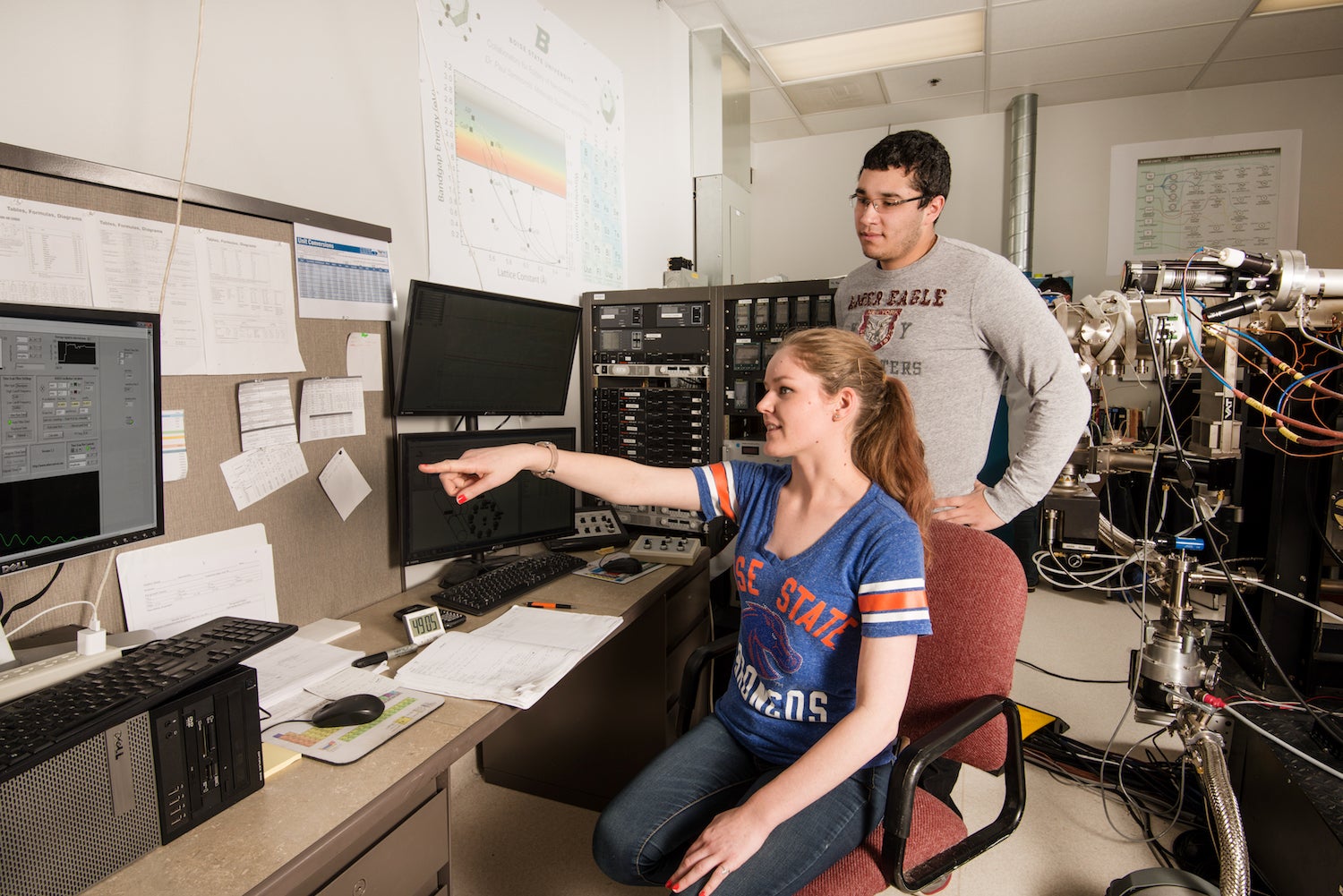

“MBE gives us atomic-level control over the materials that we’re growing that, in turn, gives us atomic control over their properties as well,” explains co-author Ariel Weltner, a senior undergraduate student in the materials science and engineering program.

One application Sautter would like to see her research implemented is in technology such as LEDs.

“We are now using what we learned and changing the surface orientation again in hopes that we can make germanium emit light. If we can make it emit light – something that germanium cannot currently do in its ‘normal’ state – then we open new pathways for novel lasing and LED applications in the mid-infrared range,” she said.

Sautter came to Boise State after earning her bachelor’s degree in materials science and engineering at Penn State. She says the care that is being put into the new materials science program that supports students like herself has been inspiring.

“Boise State has taught me a lot on many different levels. It’s inspiring to me that they took something that was from nothing and they’re building this amazing program,” said Sautter. “They consider your needs, your work/life balance, they give us benefits like massage. It shows that they care. And I feel like that is something that not every program does.”

Additional Boise State co-authors on the paper include alumni Christopher Schuck (Ph.D., materials science and engineering, ’19), undergraduate physics student Trent Garrett and third-year doctoral student of materials science and engineering Kevin Vallejo. The research also was conducted with colleagues from University of California Los Angeles and Tufts University.

To learn more about the team’s research, visit: https://www.sciencedirect.com/science/article/pii/S0022024819306839?via%3Dihub#!