Researchers from Boise State University and the National Aeronautics and Space Administration (NASA) have teamed up to develop a fully printed and flexible approach to electrochemistry using nanomaterial inks and inkjet printing. Their approach was published in the Royal Society of Chemistry’s journal, Advances, where they demonstrated the compatibility of graphene, platinum and silver nanomaterial inks with inkjet technology while printing a 3-electrode system for use in an electrochemical cell.

In the world of printed electronics, inkjet technology is a frontrunner towards a scalable path for manufacturing of sensors, circuits, and solar panels on low-cost and flexible substrates. Such an approach could have transformative impacts in consumer electronics, personalized medicine, and Internet of Things sensors in defense, agriculture and manufacturing. A limiting factor in wide-spread adoption of inkjet printing for electronics is the availability of high performance inks tailored towards unique applications.

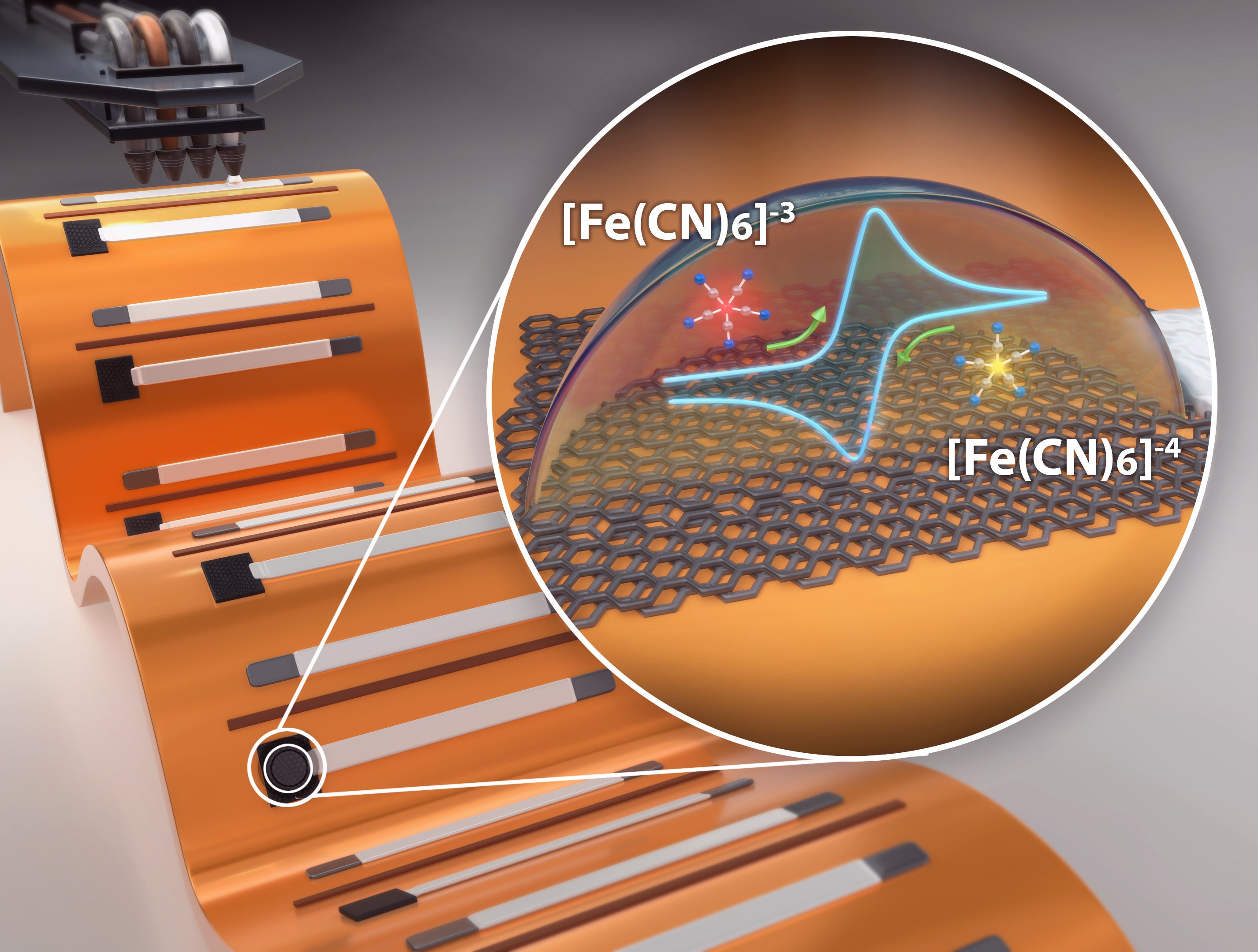

Led by associate professor David Estrada, the team developed an approach to not only create the necessary inks that enabled direct printing of electrochemical sensors; they also demonstrated the repeatability of their print process in obtaining near ideal cyclic-voltammetry (C-V) curves for their electrochemical system. Cyclic-voltammetry is a powerful technique which provides fundamental insights into reduction and oxidation of molecular species. The fact that a fully printed system provided near ideal C-V characteristics further highlights the stellar performance of these sensors in probing fundamental electrochemical processes.

“Our goal for this study is to achieve ease in tunability with the ink properties, and the printing process, in such a way that results achieve repeatable performance and can be easily modified to be suitable for many different sensor applications. By increasing efficiency in our approach, we hope to improve the utilization of graphene-based electrochemical sensors commercially,” said lead author Twinkle Pandhi, a fifth year student in the Interdisciplinary Materials science and engineering program.

The authors compared the electrochemical performance of their printed graphene electrodes to a wide range of other graphene based and inkjet printed electrodes. Their fully printed system outperformed nearly all other’s, and is the first to report on the effects cyclical bending on the device performance (this refers to a testing method in which the flexible electrodes are bent around a surface and measures how the performance changes as the number of bending cycles increased). Only graphene obtained through a high energy laser writing process came close by comparison.

“The fundamental knowledge gained from this study will help advance our work towards ion sensing with fully printed and flexible materials,” said Estrada. “This paves the way towards fully printed graphene-based ion selective sensing which has applications in human health monitoring. In addition, our materials and fully printed approach opens up the design window for in-space manufacturing of electrochemical sensors for a variety of space exploration missions — a major reason why NASA has been invested in this work.”

“The ability to print high quality graphene is of particular importance as it enables NASA to expand its in-space manufacturing portfolio into a wider range of sensors and electronics, including electrochemical sensors. The initial printed graphene characterization has highlighted graphene’s excellent electrochemical performance, lending it to applications ranging from astronaut health monitoring to food safety and environmental monitoring,” said Jessica Koehne, a co-author on the study and a scientist at NASA’s Ames Research Center.

This collaborative work was funded in large part by the National Aeronautics and Space Administration with contributions from the Department of Energy for the development of platinum inks for harsh environments.

Article Citation: T. Pandhi, C. Cornwell, P. Barnes, J. Cox, C. Xiong, P. Davis, H. Subbaraman, J. Koehne, D. Estrada, “Fully Inkjet Printed Multilayer Graphene Electrodes for Flexible Biosensing Applications,” RSC Advances, 10, 38205-38219 (2020).