Our research group is on the mission to discover and experiment with the possibilities of a new type of material. To do this, special machines are often bought or made by us that measure attributes of this material. In our lab we currently have a variety of machines that help us accomplish our goal. Browse below to find out what they can do and what we do with them.

Lab Equipment

Synthesis

Single Crystal Growth Furnace

NiMnGa crystals are artificial and need to be grown in specific conditions. In addition, the only current demand for NiMnGa crystals is for research purposes. Consequently, purchasing a NiMnGa crystal is very expensive. Therefore, we grow our own crystals with this furnace. Like many of our machines, we are proud to say that the furnace was constructed by one of our students, Doug Kellis. Since his graduation, other students have made improvements and we are constantly increasing the furnace’s usefulness.

Annealing Furnace

This tube furnace is used to anneal and heat-treat the crystals. In the furnace, we can pull a vaccuum and flush the oxygen out with argon. The pressure in the Annealing Furnace can be set within the range: 4.3E-4 to 1200 mbar. The maximum temperature is 1100 C.

Reitel Furnace

The Reitel Furnace is an induction heated casting machine. We use this furnace in conjunction with the vacuum by lowering a quartz tube into the furnace having pulling a vacuum in the quartz tube. We can also flush argon through the chamber and set a desired pressure.

Characterization

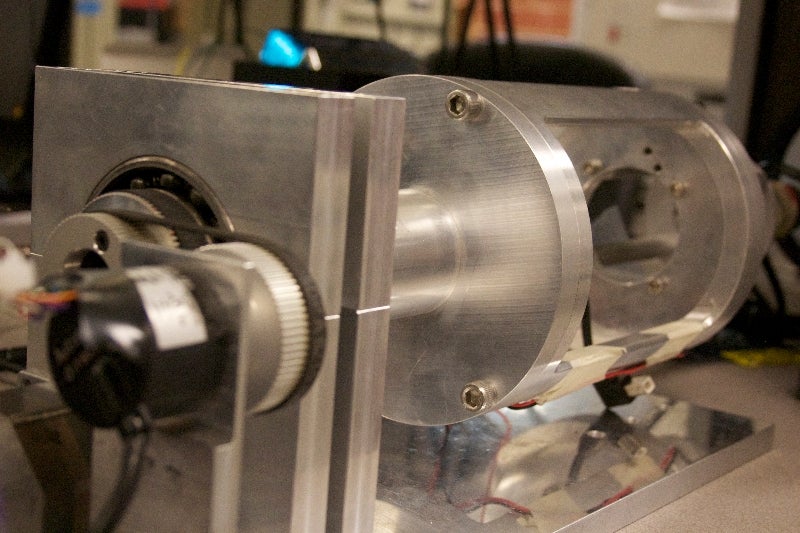

Optical Magneto-Mechanical Device (OMMD)

The OMMD rotates a sample in the VSM with a constant magnetic field (using the VSM magnet) with a camera. Using the images acquired during rotation, we can identity twins boundary motion and determine strain. The OMMD can also vary the temperature of the sample within the temperature range: -10 to 70 degrees Celsius.

Multi-beam Optical Sensor (MOS) Thermal Scan

The MOS thermal scan is designed to acquire and analyze stress/strain and curvature data. The main components of the system are:

- Multi-beam Optical Scanning (MOS) Laser

- Heated Substrate Chamber

- Turbo Molecular Pump (TMP)

- Pressurized Gas Delivery

- Temperature Sensor Unit (BandiT)

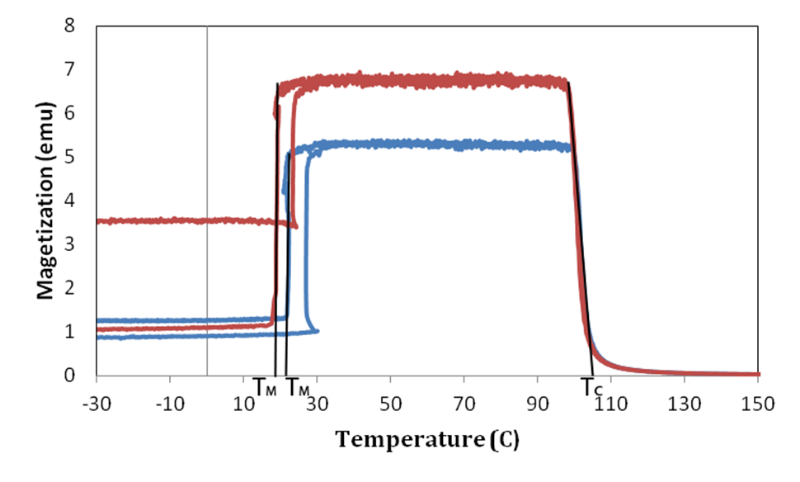

Vibrating Sample Magnetometer (VSM)

The MicroSense VSM was donated to us from Micron in 2004. Since we’ve had this machine, our researchers have customized the VSM to our research needs. The VSM is capable to performing the following tests: Temperature, Hysteresis, Virgin Curve, Anisotropy, Switching Fields.

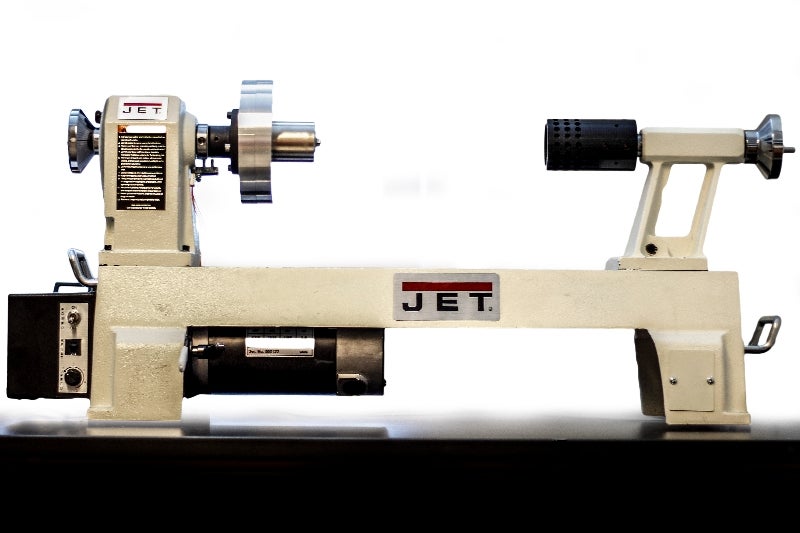

Rotary

The Rotary is for the fatigue testing project. We needed a way to test the fatigue life of a multitude of samples. This rotary can hold up to 60 samples at once. With this machine we rotate the samples around a powerful magnet a large number of revolutions, allowing us to determine the number of cycles our samples can endure before failure.

Dynamic Maneto-Mechanical Device (IBAG)

The IBAG, similar to the rotary, tests the fatigue value in a sample. The IBAG tests one sample at a time and runs millions of cycles at up to 4000 revolutions per minute. Also, while the sample is going through the cycles, the sample’s deformation and strain are recorded, resulting in a well defined story of the samples fatigue life.

Stress-Strain Tester (Zwick)

The Zwick gives stress versus strain curves. This machine was gifted to us from Switzerland where Peter Mullner used to study. The Zwick was shipped to us poorly, and the students at BSU were given yet another opportunity to show their engineering skills by revitalizing a custom machine with a manual written in German. Nonetheless, the Zwick can also be used with the presence of a two Tesla magnetic field and a camera capturing the changing sample surface as twins shift at specific stresses.

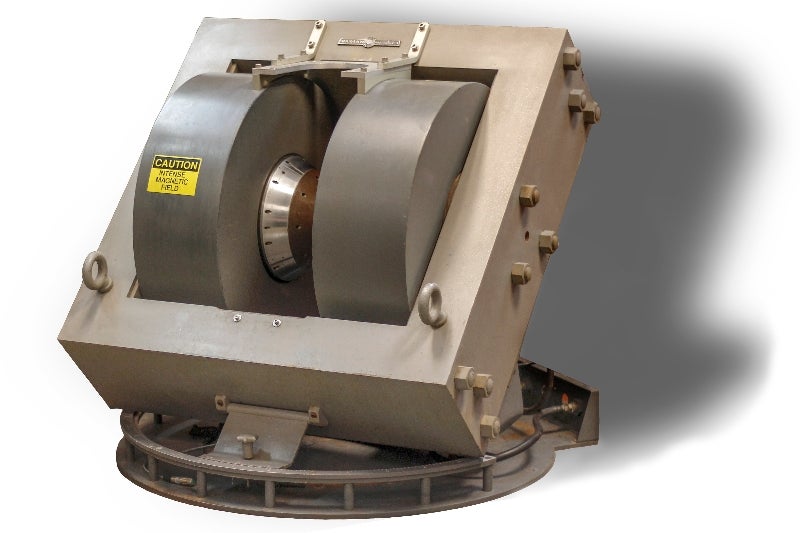

Agilent VSM

The Agilent VSM is not yet in use. It was donated to Boise State at the beginning of the summer. We also plan to use the magnetizer shown in the bottom-right of the collective picture to create a pulse magnetic field.

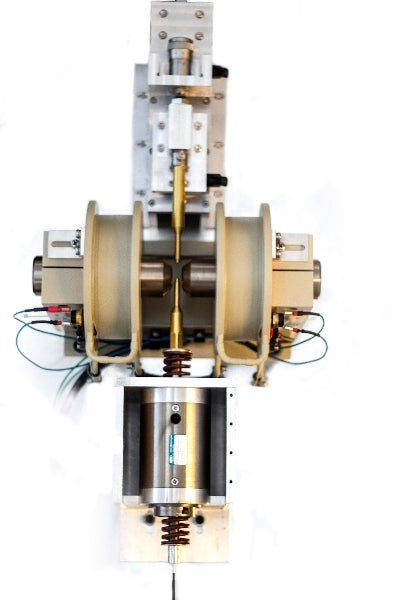

Magneto-Mechanical Test Apparatus (MMTA)

The Magneto-Mechanical Test Apparatus is used for cyclic mechanical loading and unloading samples from 1 Hz up to 800 Hz. It is an instrumented test apparatus consisting of a load cell, a displacement transducer, an inductive pickup coil, a linear voice coil motor and an adjustable electromagnet. It is used to investigate the power generated as a function of frequency (10 to 800Hz), magnetic field strength (0.1 to 1.0T), and strain (0.5 to 3.5%).