Amanda White, Adam Croteau, Catherine Gale, Sarah Pooley, Jacob Tenorio, Dr. Don Plumlee, Dr. Ken Cornell, Dr. Jim Browning

Background

- Bacteria/biofilms in agricultural systems pose a problem in cross contamination as well as increasing safety risks for people who encounter them

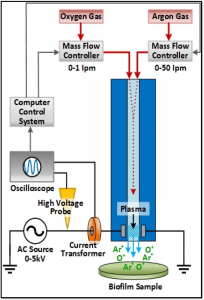

- A Low Temperature Co-fired Ceramic system is utilized to develop a Cold Atmospheric Plasma (CAP) operating outside of a vacuum

- A parallel plate capacitive discharge source delivers plasma capable of removing biofilms and bacteria

CAP Description

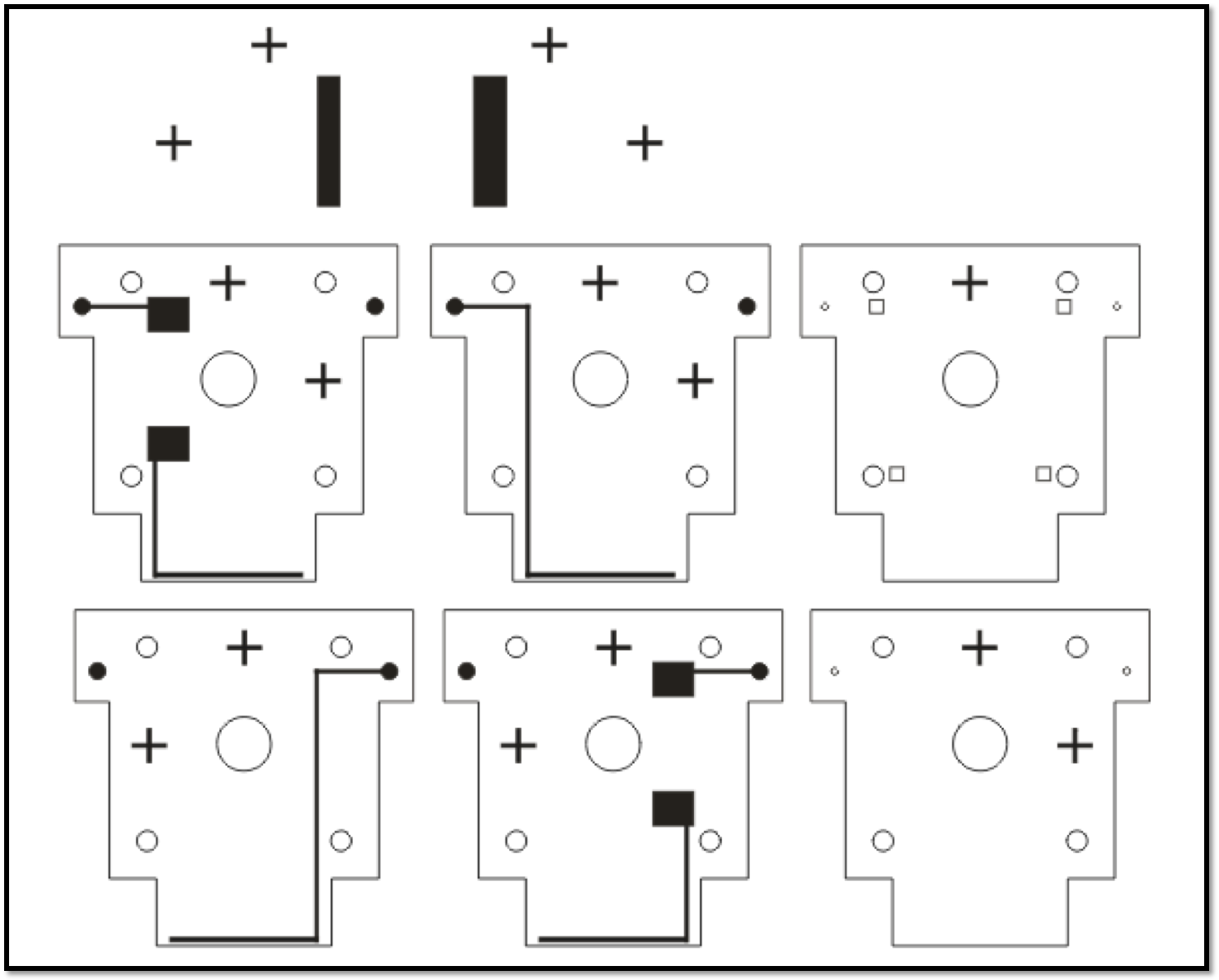

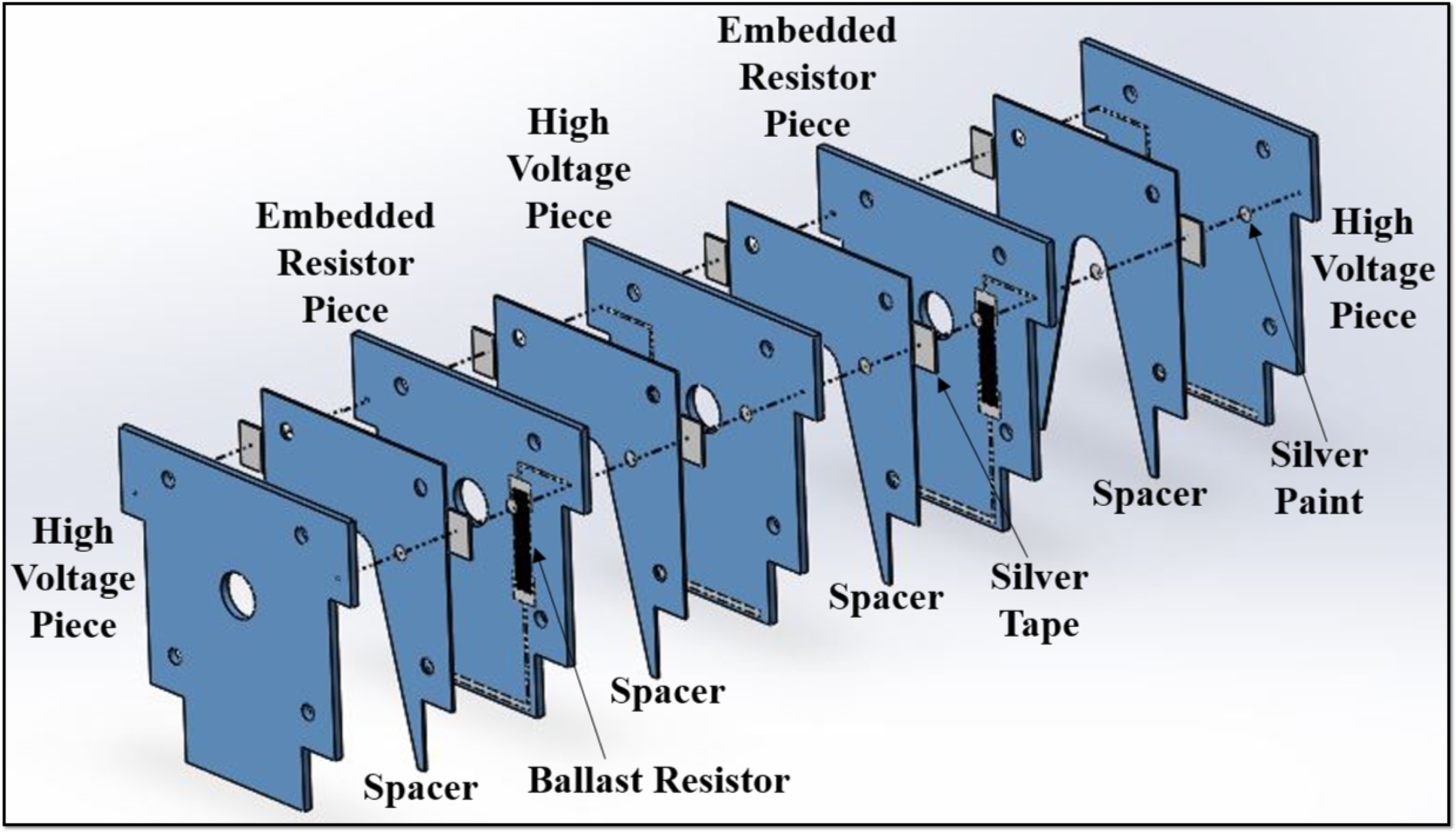

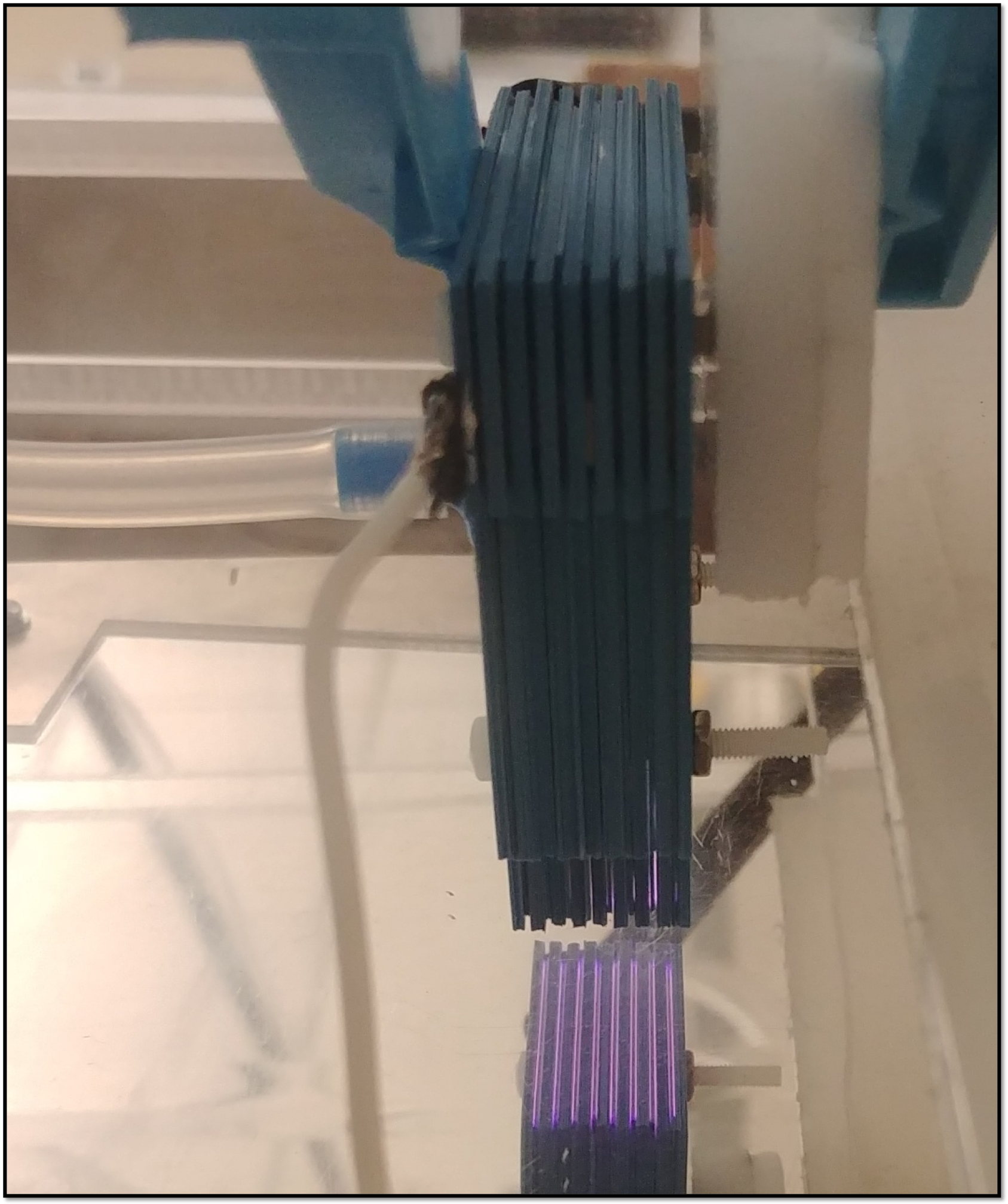

- These devices are built so that two silver conductors, embedded within thin layers of (127μm) of LTCC acting as a dielectric are placed across from each other

- A 20 kHz AC voltage (2-5 kV) is applied to the electrodes to generate the plasma between the plates

- Plasma is then directed towards the biofilms by the gas flow

Fabrication Process

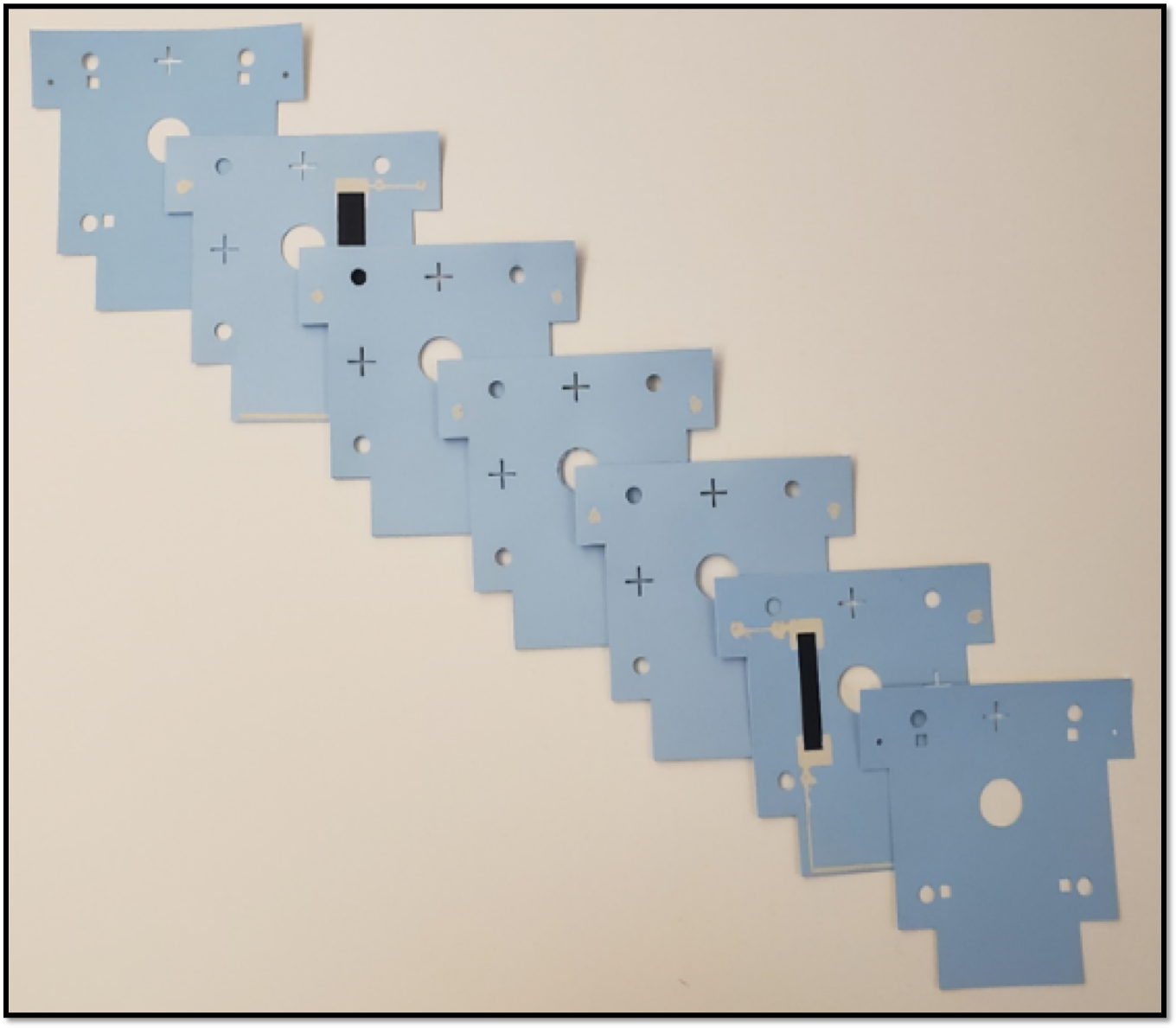

- LTCC is laser cut into device shape

- Silver and resistor paste are screen printed on outer layers of each single plate

- Layers pressed together with 5 mil dielectric layers

- Devices baked in kiln to just below 900˚C to cure silver

- Header pins are attached to outer plates

- Inner plates are connected together with silver tape to outer plates

- Wires connect voltage source to header pins

Implementation of Embedded Resistor

- The development of an array of parts allows for a larger area of plasma discharge

- Internally fabricated ballast resistors (150 kΩ) added to design to develop 8 CAP sources is being tested

Results

Fabrication of Embedded Resistor and High Voltage pieces are up to 90% more efficient than previous generations with increased longevity.

Future Work

Further research will be conducted on the fabrication of radial arrays which will be utilized to study biofilm removal inside pipes.

Funded By

This research is supported by the U.S. Department of Agriculture under the NIFA grant # 2018-67018-27881 and is also supported by the Helmsley Charitable Trust and Boise State University College of Innovation and Design as a Vertically Integrated Projects course in Plasma Medicine.

Additional Information

For questions or comments about this research, contact Amanda White at amandawhite@u.boisestate.edu.